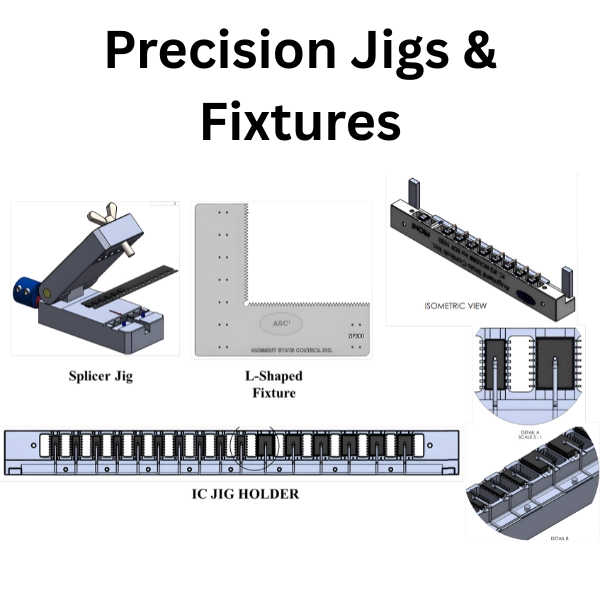

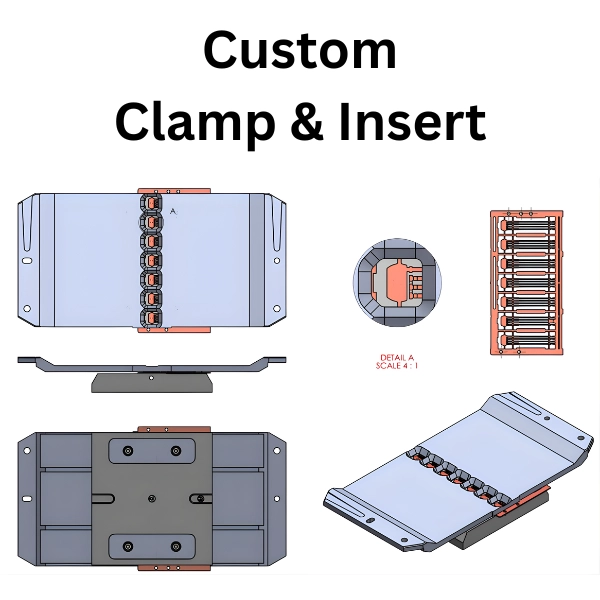

Custom Fabrication of Jigs & Fixtures

We provide custom-designed and precision-fabricated jigs and fixtures tailored for the semiconductor, electronics, and automotive industries, where accuracy, repeatability, and reliability are non-negotiable.

Our jigs and fixtures are engineered to improve production efficiency, ensure dimensional consistency, and reduce operator variability across inspection, assembly, machining, and testing processes. Each solution is built based on your actual application requirements, machine interface, tolerances, and workflow, ensuring seamless integration into your existing production line.

Key Capabilities & Benefits:

-

Precision-built jigs and fixtures for inspection, measurement, alignment, and assembly

-

Designed for CMM, vision systems, laser systems, and automated equipment

-

Supports high-mix, high-precision manufacturing environments

-

Improves repeatability, cycle time, and measurement accuracy

-

Durable materials suitable for cleanroom, ESD-sensitive, and production-floor use

-

Fully customized—from concept, design, fabrication, to on-site fitting and validation

Whether for semiconductor packages, PCB assemblies, automotive components, or precision parts, our solutions are built to hold parts exactly where they should be—every time. Old-school precision, modern execution. Built right the first time. 🔧✨