Automation & Integration

End to end automation setups that streamline production, reduce manual handling, and enhance workflow reliability. Includes robotic integration, machine connectivity, conveyor solutions, and custom engineered systems. Designed to improve efficiency while maintaining strict process control.

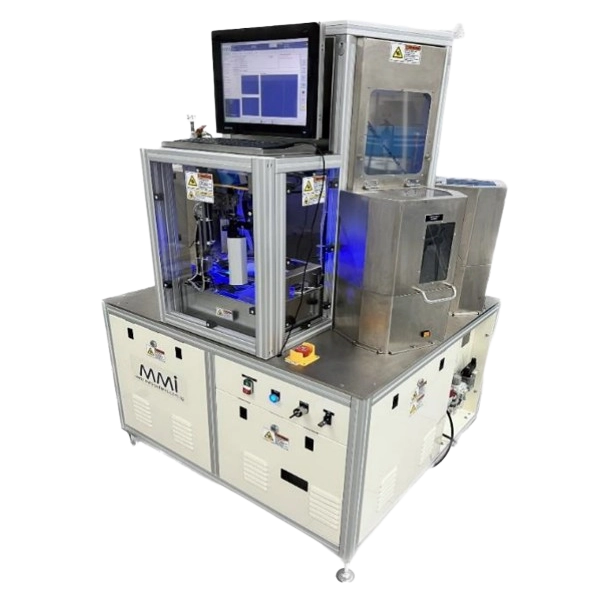

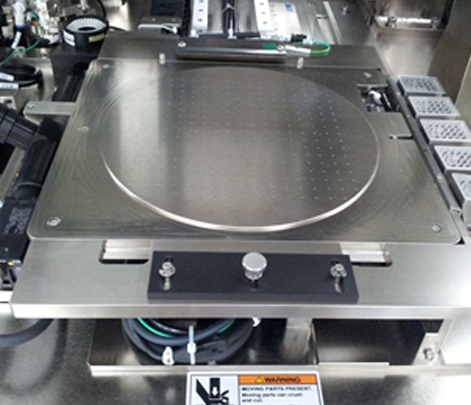

The WSI, a Four Open Cassette Wafer Sorter for 100mm through 200mm wafer sizes. It offers the most compact size with four cassettes loading for continuous

operations with minimum intervention. All models come with standard robotic components for longest reliability and support. It was developed with a unique recipe development and LED beam carrier scanning for perfect wafer mapping. Each system can be tailored to your specific needs by add-on options or specific request.

MAIN FEATURES

Using Robotic Arm that provide speed and accuracy for sorting and placement of wafers. Our LED beam scanner offers accurate scanning during cassette

mapping.

• 4 stations loading capacity

• Handle Horizontal loading

• Wafer robot mounted with LED beam scanner

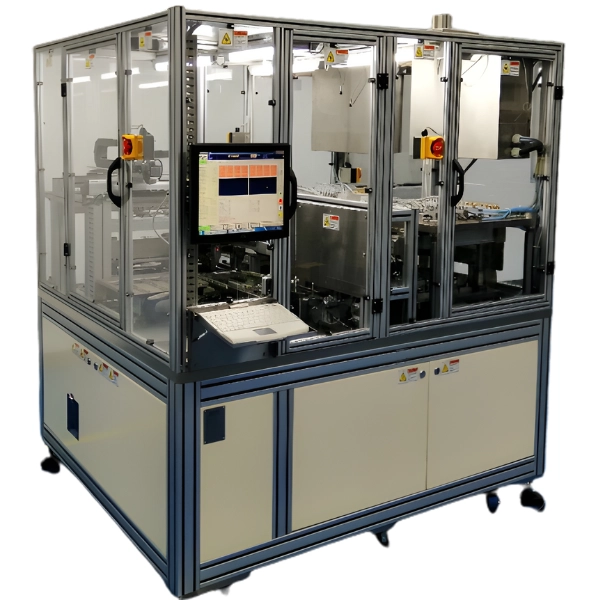

• Single paddle with Vacuum backside handling

The TIE designed to precisely pick and place IC Lids to high temperature sealing station for IC encapsulation process. Dual sealing stations with precise temperature control accuracy and fully automatic processes to improve productivity and efficiency. Each system also can be tailored to your specific needs by add-on options or specific request.

Thermal IC Encapsulation Features

Dual Sealing Stations

• High yield and throughput

• Individual PID temperature controller to provide consistent temperature control across all DUT

• Precise temperature control accuracy

Lids Loading Features

The TIE tray loader station allow user to load and unload tray at any point of time

• Lids load into customize ESD tray

• Able to stack up to 20 trays

• Full automatics tray loading and unloading mechanism

• Empty tray to be retrieved at any time even when the machine is running.

Vision Inspection Features

Uses vision system for orientation and IC packages check

• Detect lead frame orientation and Lids based on the recipe selection

• Detect correct loading of IC package and Lids

• Easy teaching using pattern recognition vision software

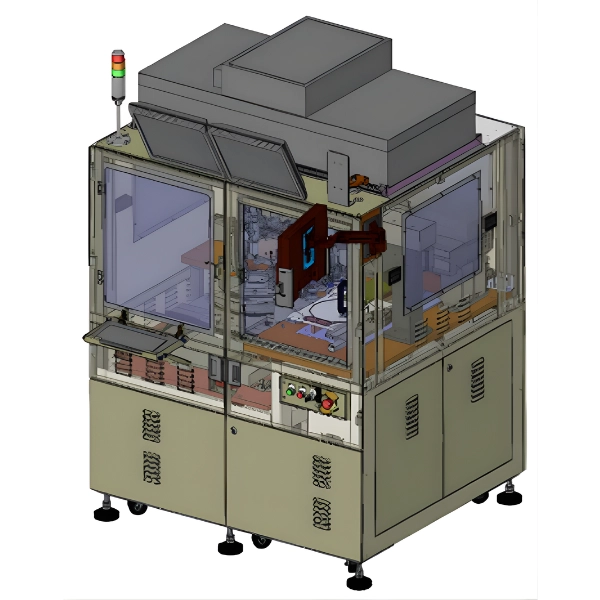

This system is designed to precisely pick and place precision lens, inspect lens’ surface cosmetic defects using our in-house developed AOI, and output the good lens into wafer format tray or other types of trays for downstream process.

Application / Function

Precision pick and place of precision component in wafer level

Key Feature / Technology

- From manual to fully automated

- Cleanroom specification

- Vision system inspection

- Wafer level pick and place with force control

- Wafer placement with flexibility configuration

- And more…

Labour Substitution and Productivity Data

- Reduce labour numbers and cost

- Improve monthly productivity

- High return on investment

- Reduction in cleanroom production space

- And more…

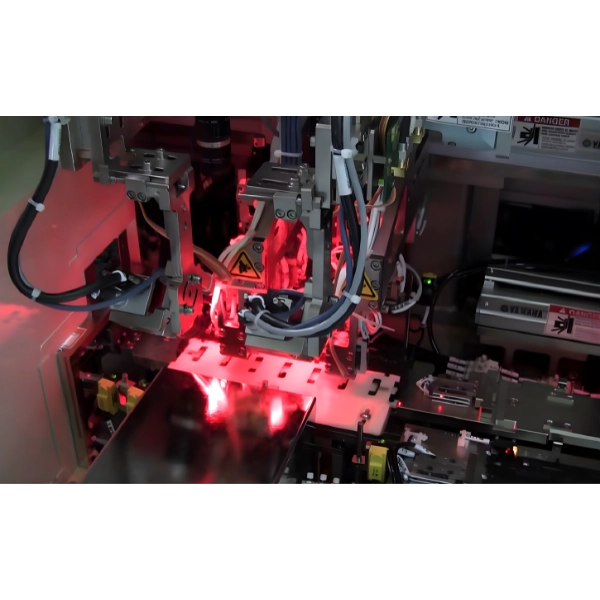

Application / Function

Designed to measure and validate PZT capacitance, resistance and shorting circuit of component on tray laser mark on reject and sort to reject tray

Key Feature / Technology

- Fully automated with high precision

- Probing technology

- High speed measurement of capacitance, resistance, open circuit and polarity test

- Precise probe position with aided vision system

- Laser dot marking for reject

- Close loop feedback of probe condition

- And more…

Labour Substitution and Productivity Data

- Double productivity to previous semi-auto process

- Reduce labour numbers and cost

- Reduction in cleanroom production space

- High return on investment

- Reduction in human interface and handling led to quality improvement

- And more…