Laser Application

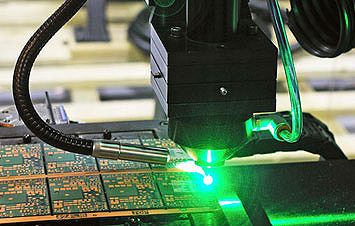

Industrial laser solutions for marking, cutting, engraving, and material processing. These systems provide high speed output, clean edges, and stable performance across metals, plastics, semiconductors, and specialized materials. Built for operations that need precise results with minimal maintenance.

LAYER-BY-LAYER ABLATIONS

Decapsulation (Decap) is a process that most Failure Analysis labs use on a routine basis.

The FALIT™ uses our patented laser technology to allow an operator to remove mold compound all the way through the lead frames to the substrate. The entire process is 100% controllable by the operator through our Graphic User Interface. The FALIT™ laser can accurately remove the entire compound, individual layers or sections of the mold compound (operator defined). The FALIT™ offers a safe and more accurate process for IC laser decapsulation.

Programmable Gas Assist comes standard to enhance the lasers capabilities while processing. Additional standard features include a camera system with external monitor cross hair generator, and process viewing for part alignment. An optional vision system can provide image recognition for part alignment or hole inspection.

Large Filler Mold Compounds for Copper

Our Digital ICO™ (IC Optimized) laser was specifically developed for removing the newer mold compounds associated with gold, copper, palladium, aluminum, and silver alloy bond wires. This compound typically has larger fillers and more filler material making it difficult even for traditional laser decapsulation. The greater laser power required to remove this new compound can sometimes damage very small wires or leave excess compound around the wires. Our new proprietary laser technology totally eliminates this problem and can even enhance results on traditional mold compounds.

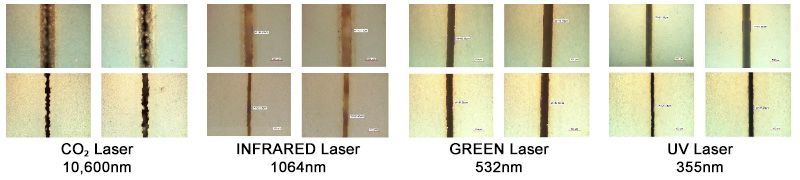

The 532nm green laser within our FALIT ™ and the FALIT Duo™ offers FA labs a longer depth of focus for cross-sectioning thicker parts with the draw-back of having a larger spot size and larger Heat Affected Zone (HAZ) than the UV laser. The green laser has been employed by many semiconductor failure analysis labs for cutting parts out of PCBs where the solder balls, and surrounding components, cannot be damaged. The green laser is also used for cutting electronic components in half as a pre-process to either Focused Ion Beam (FIB) cross-sectioning, or mechanical polishing. Our experience shows that we can get to within about 75-microns from the area of interest without damaging it while using the green laser. As, in most cases, our process for preparing a sample for solder ball adhesion inspection does not melt the solder ball, the FA lab is able to quickly process a sample to further analyze the solder-to-pad adhesion without introduction of external force or heat which might otherwise call into question the inspection results.

With the optional 355nm UV laser within our FALIT ™ and the FALIT Duo™ offers higher precision, a smaller spot size, and a smaller Heat Affected Zone over the green laser. The UV laser is recommended where the failure analysis lab processes, via cross-sectioning or cutting, a wider array of different packages, or when dealing with silicon wafers. Cuts from the UV laser are much more fine which allows more bulk material to be removed in an effort to get closer to the area of interest during cross-sectioning. Silicon wafers can be sliced and diced with up to 10-watts of UV power. As UV is absorbed by most materials, it provides the FA lab with the flexibility to process a wider array of parts.

X Sectioning Gallery

Diamond saws and other mechanical methods of cross-sectioning put physical stress into a part. It is then difficult to determine whether the defect (such as delamination) was already there or caused by the mechanical process itself. Laser cutting presents NO such problem. There is no mechanical force introduced with a laser. Therefore, cross-sections can be made much closer to the actual defect diminishing the polishing time or in many cases eliminating polishing altogether

SCRIBE – DeLid Gallery

Lids and covers over components that need to be analyzed have always been a problem in the Failure Analysis Lab. Mechanical micro routers can damage internal parts, require complicated fixtures, and even destroy samples. With the FALIT™ Laser this process is quick, simple, and successful. A Green laser (532nm), or a UV laser (355nm), can be used to cut the top of a lid completely off.

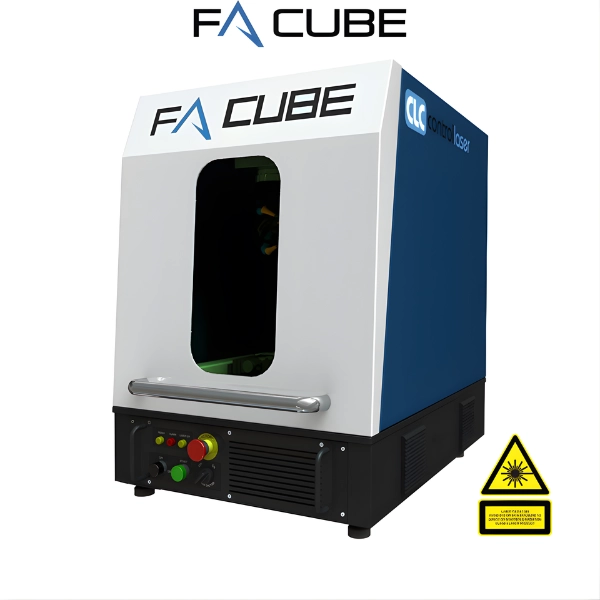

The FA Cube™ was specifically designed with the semiconductor failure analysis and forensics Labs in mind. Our compact laser semiconductor laser decapsulation system provides clean and accurate laser IC Laser Decapsulation with reliable results. The FA Cube™ incorporates the same patented process as our FALIT™ series. This patented laser process uses multiple laser configurations to provide clear and precise test samples for nearly every type of semiconductor failure analysis and forensic application.

- Ideal Solution for IC Laser Decapsulation and removing large filler mold compounds for copper.

- Cleanly remove mold compound using laser technology rather than the traditional unsafe acid process.

- Expose Wire Bonds without damage to other components.

- Fixed Co-Axial Optical Camera Lens (options available).

- Optional X-Y stage table and Self-Centering Fixture.

- Easy sliding door with large viewing window and internal workspace.

- Compact Motorized Z-Axis for accuracy (optional).

- FALIT™ Light Laser Software interface included. Basic GUI for Failure Analysis.

Software

Our essential FA Cube intuitive software allows the laser decapsulation of IC components for bond and die inspection. Aside from the standard software features, we offer a variety of modules and tools to extend the abilities of the machine per request.

Optional Software Tools:

- Gasket Module

- Polygon tools/Ortho Mode

- Surround Mode

- Text Mode

- Image Import

- Template Creation

- Recipe Manager

IC Silicone Gel Compound Removal

A growing number of IC design are utilizing a gel type encapsulation compounds.

Whether it is for diaphragm on the die of a pressure detection device. Less stress on the newer thinner dies, or extreme temperature variation and vibrations faced by automotive industry control semiconductor devices, this silicone gels seems impervious to chemical, plasma or even standard laser decapsulation..

Most power and MEM devices are silicone encapsulated.

A Case Note.

The SIFEL® gel from SHIN-ETSU is a remarkable material used in many semiconductors. Common devices using SIFEL® gel are MEMS devices and pressure sensors where low-stress encapsulation of sensitive electronic devices, but maximum protection against heat and chemicals, is important. SIFEL®’s advantages present unique challenges to failure analysis labs that need to remove the gel in order to determine why a device failed. With it’s near-impervious chemical resistance, acids and many other chemicals have no effect on the gel.

CLC has developed a laser application that uses SIFEL® gel properties to the advantage removing it

Using our proprietary ICO laser, and a carefully engineered removal recipe, the majority of the gel can be removed without too much problem.

CLC FALiT Gel Decapsulation Safely Removes Gel Compound “ALL THE WAT TO THE DIE” in second’s.

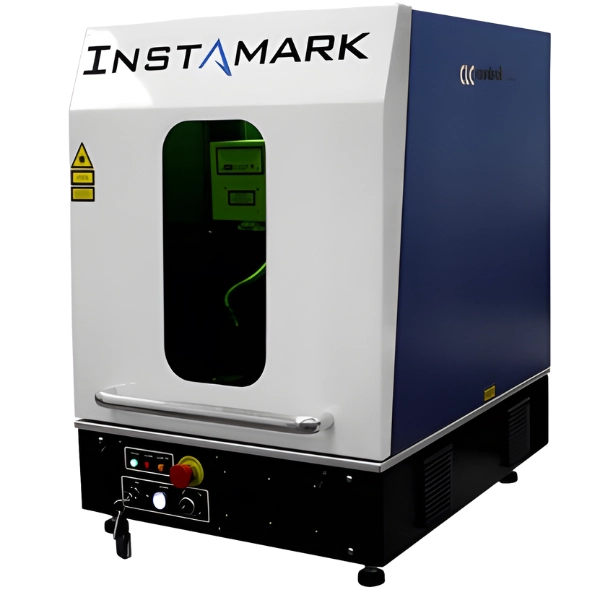

INSTAMARK® laser marking and engraving system is capable of marking and engraving the widest range of materials such as steel/stainless, aluminum, titanium, ceramics and some plastics. With your choice of laser type [Q-Switched Fiber, or MOPA Fiber], power level, the capability to transform from a class I/II laser system, to a class IV laser system, there is not much that this laser system cannot mark on. Alpha-numerics, graphics, and barcodes can be marked up to 1,250 characters per second using our state-of-the-art high-speed, high-accuracy, galvo head. The affordable price and compact desktop size makes the Instamark® perfect for small shops with limited space.

Standard Specification

- Alpha-numeric, graphics, and barcodes can be marked up to 1,250 characters per second

- Transformable Class I/II or Class IV Laser System

- Laser power, 20 Watts, 30 Watts or 50 Watts

- 7” lasing area with standard lens

- 9″ x 11.75″ x 2″ lasing area with optional 11.75″ lens

- 12″ x 17″ x 7″ working area in Class I/II mode

- Accommodates Q-Switched or MOPA Fiber Laser markers and engravers

- Can be easily integrated into any production or assembly line for on-the-fly marking

- Integrated Windows Computer, with External Monitor/Keyboard/Mouse, Included

- Enclosure Illumination

- Exhaust Port and Plumbing

- Compact and Rugged Desktop System, L28.3″ x W22.5″ x H31″

- Optional Rotary Available

- Building Block Design

- 115 VAC/230VAC Operation

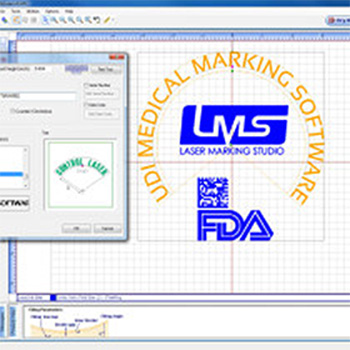

- Laser Marking Studio™ (LMS) Software – User friendly laser marking GUI included

Control Laser is a pioneer being the first laser marking company to fully implement FDA, GS1 and HIBCC® UDI medical marking standards into laser marking systems. CLC Medical UDI-Mark™ systems mark a variety of components and materials with FDA UDI compliant AIDC , GTIN, GLN and HIBC marks. The materials used in the medical industry include: metals, plastics, composites, ceramics, and more. Medical device manufacturers have relied on our compliant systems to provide the traceability requirements of medical marking because we understand these complex rules.

GS1 and HIBCC UDI Medical Laser Applications

Control Laser’s GS1 and HIBCC UDI medical laser marking systems come in a wide variety of wavelengths, power levels and beam profiles which give us the ability to mark any type of material or part.

Traceability is the core purpose for implementing the UDI marking rules since every piece that goes into a human needs to be accounted for. Being able to trace the part back to the source is imperative if there is some complication, but providing a mark that does not create an issue is also very important. With CLC’s experience in medical marking allows us to understand this application and assist our customers in providing proven UDI laser marking systems

The Medical UDI-Mark™ laser marking systems provide both GS1 and HIBCC UDI laser markings on a variety of components used in the medical industry. With over 50-years of experience in the medical laser marking industry, Control Laser can provide you with the complete turn-key solutions you need for your FDA compliant marks.

- FDA Compliant Laser Marker

- Sub-millimeter and above marking sizes

- Windows Computer included

- Enclosure Illumination

- Inspection and mark verification solution (optional)

- Exhaust Port and Plumbing

- Rugged Enclosure

- Optional Rotary Available

- 115 VAC Operation (220 VAC Optional)

- Laser Marking Studio™ (LMS) Software – User friendly GUI included.

Some advantages of working with Control Laser for your UDI medical marking needs:

- Mark permanent GS1 and HIBCC traceability barcodes onto medical appliances and implants

- Meet the FDA regulations regarding the biocompatible marking of GS1 and HIBCC UDI codes onto medical devices

- Verify the parts and marks using our optional part and mark verification devices

- Mark flat, 3D, and cylindrical parts with ease in nearly any font and all of the FDA compliant GS1 and HIBCC codes

Dental Clamps , Cardiac pacemakers, defibrillators, guidewires, catheters, hearing aids, brachyseeds, orthodontic components, prosthetics, cannulae, Hypodermic Needles, Hemostats, Surgical Screws, Stints and surgical tools are just a few of our proven applications!

We also have Medical UDI-Mark™ systems for micro-welding and micro-cutting intricate and sensitive parts used in the medical industry.

RETINA G5587 was developed, specifically for Laser Grooving for the semiconductor wafer industry. It has built-in auto load & unload system, transport manipulator, cutting platform, coating system, optical modules, fume extractor to support the needs of a fully automatic semiconductor wafer grooving process.

Developed by NASA in the 1970s – 1980s as part of the space shuttle program, as the risk of damaging the delicate electrical conductor was apparent with traditional stripping methods/systems.

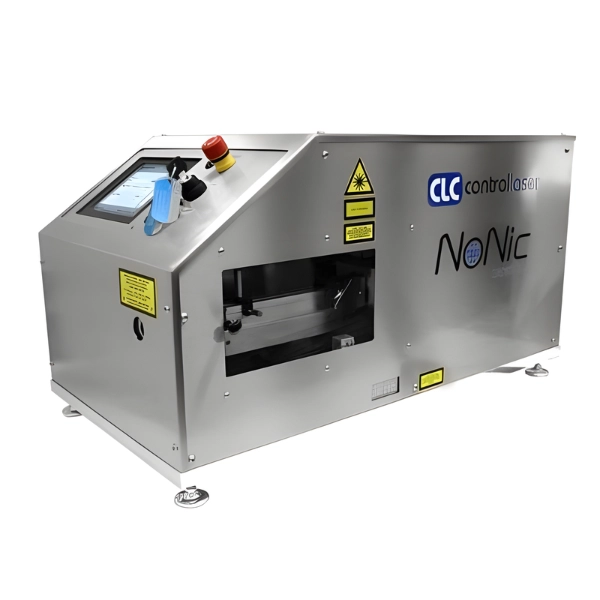

The NoNic™ Benchtop provides the most accurate tools to strip and slit wire insulation successfully.

No other product on the market can compare to our system’s ability to strip and slit most varieties of wire cleaner, faster, and easier than ever before. The NoNic™ Benchtop laser series is the premier solution for removing troublesome wire insulation effectively without harming the wires underneath. The NoNic™ Benchtop comes in a newly redesigned compact Benchtop configuration for easy access and quick operation. This system can safely strip wires as small as 0.030″ and handle tolerances as tight as .001″ as well. We can safely remove 99% of all insulation with 10 second changeover or less. No more need for exactor knives and tweezers – Our NoNic™ Benchtop products take all the tedium and frustration out of the equation.

- Strip difficult wire insulation safely with No Damage to the wires underneath – including Teflon® material.

- Easily Strip a wide range of wire types, sizes, and gauges. Sizes as small as 0.030″ with tolerances as tight as .001″

- Quick Changeover from one wire size to another with our included tooling.

- Built-in User friendly laser software for processing wires with ease and accuracy.

Each NoNic™ desktop system comes with 5-sets of wire guides. The wire guides are the tooling that determine the gauge of wire that the system can process. A total of 10-sets are available for wire diameters from 0.030″ (20AWG, 0.51760mm²) to 0.75″ (8/0AWG, 293.8908mm²). Custom wire sizes are available upon request.

Market Leading Technology

BOFA designs, develops and manufactures fume and dust extraction systems for a wide range of industrial sectors and applications. BOFA creates technologies that protect the health of millions of workers around the world while at the same time improving industrial process performance by minimising disruption to production.

These products ensure operator safety by capturing harmful dust and fumes which are generated during industrial processes while minimising disruption on production.

Why You Need Fume & Dust Extractor?

All businesses have a legal obligation to ensure a safe working environment for their people.

To maintain a dust and fume-free workplace through the removal of solid particles (particulates), liquid droplets (usually aerosols or mists) and vapours or gases (fume). This is critical, because the health consequences for employees working in a hazardous environment can be significant and permanent.

Work related lung illnesses (occupational respiratory disease) include asbestosis, silicosis, COPD, asthma, emphysema and lung cancer.

Award Winning Technology

BOFA was awarded the Queen’s Award for Enterprise 2017 for Innovation!

In 2017 BOFA was awarded the Queen’s Award for Enterprise: Innovation for our revolutionary Intelligent (iQ), Operating System , which is transforming the way that organisations around the world are able to protect the health of employees and improve production processes. Our Queen’s Award for International Trade in 2012, recognises that over 90% of our products are now exported overseas.