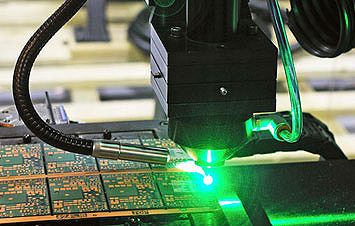

Decapsulation (Decap) is a process that most Failure Analysis labs use on a routine basis.

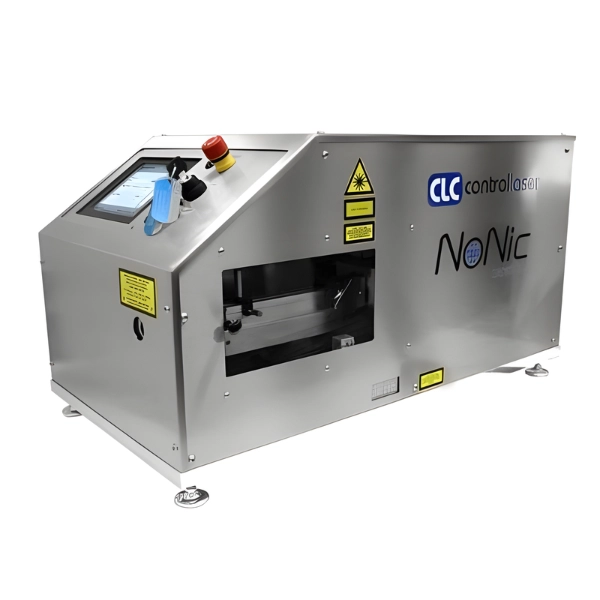

The FALIT™ uses our patented laser technology to allow an operator to remove mold compound all the way through the lead frames to the substrate. The entire process is 100% controllable by the operator through our Graphic User Interface. The FALIT™ laser can accurately remove the entire compound, individual layers or sections of the mold compound (operator defined). The FALIT™ offers a safe and more accurate process for IC laser decapsulation.

Programmable Gas Assist comes standard to enhance the lasers capabilities while processing. Additional standard features include a camera system with external monitor cross hair generator, and process viewing for part alignment. An optional vision system can provide image recognition for part alignment or hole inspection.

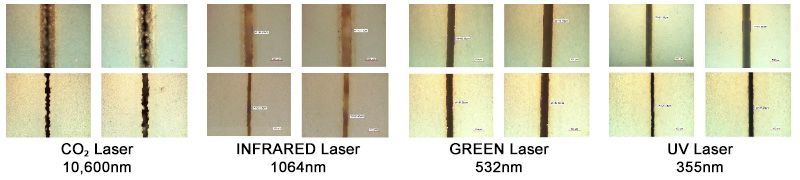

Large Filler Mold Compounds for Copper

Our Digital ICO™ (IC Optimized) laser was specifically developed for removing the newer mold compounds associated with gold, copper, palladium, aluminum, and silver alloy bond wires. This compound typically has larger fillers and more filler material making it difficult even for traditional laser decapsulation. The greater laser power required to remove this new compound can sometimes damage very small wires or leave excess compound around the wires. Our new proprietary laser technology totally eliminates this problem and can even enhance results on traditional mold compounds.