Developed by NASA in the 1970s – 1980s as part of the space shuttle program, as the risk of damaging the delicate electrical conductor was apparent with traditional stripping methods/systems.

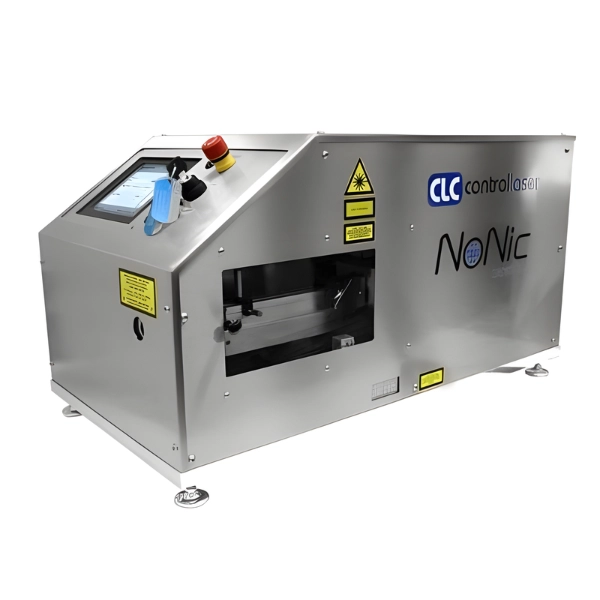

The NoNic™ Benchtop provides the most accurate tools to strip and slit wire insulation successfully.

No other product on the market can compare to our system’s ability to strip and slit most varieties of wire cleaner, faster, and easier than ever before. The NoNic™ Benchtop laser series is the premier solution for removing troublesome wire insulation effectively without harming the wires underneath. The NoNic™ Benchtop comes in a newly redesigned compact Benchtop configuration for easy access and quick operation. This system can safely strip wires as small as 0.030″ and handle tolerances as tight as .001″ as well. We can safely remove 99% of all insulation with 10 second changeover or less. No more need for exactor knives and tweezers – Our NoNic™ Benchtop products take all the tedium and frustration out of the equation.

- Strip difficult wire insulation safely with No Damage to the wires underneath – including Teflon® material.

- Easily Strip a wide range of wire types, sizes, and gauges. Sizes as small as 0.030″ with tolerances as tight as .001″

- Quick Changeover from one wire size to another with our included tooling.

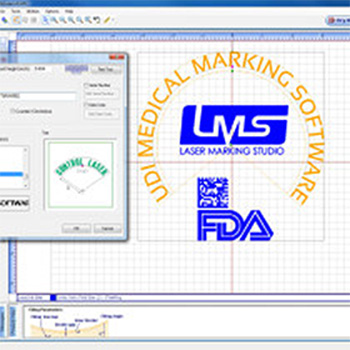

- Built-in User friendly laser software for processing wires with ease and accuracy.

Each NoNic™ desktop system comes with 5-sets of wire guides. The wire guides are the tooling that determine the gauge of wire that the system can process. A total of 10-sets are available for wire diameters from 0.030″ (20AWG, 0.51760mm²) to 0.75″ (8/0AWG, 293.8908mm²). Custom wire sizes are available upon request.