OGP Products

OGP (Optical Gaging Products) is a division of Quality Vision International Inc (QVI®), a global leader in precision multisensor metrology systems for industrial quality control. OGP specializes in measurement technologies that help manufacturers ensure components meet exact design specifications.

Since its launch in 1992, the OGP SmartScope® product family has become one of the most widely used and versatile dimensional measurement systems worldwide. SmartScope systems are designed and produced at QVI’s headquarters in Rochester, NY, USA.

In addition to SmartScope, OGP offers shaft measurement systems, multisensor CMMs, 3D scanning solutions, and other specialized measurement systems designed for high-volume production.

The SmartScope E7 is a benchtop, fully automatic 3-axis video measuring system designed for high-precision dimensional inspection and quality control. It is part of the SmartScope E-Series and is built for reliable, repeatable measurements in production and inspection environments.

The system uses a fixed-lens IntelliCentric optical system paired with a high-resolution color camera and digital zoom, allowing fast magnification changes without mechanical lens movement. This design improves stability, speed, and measurement accuracy. Advanced LED illumination, including coaxial, profile, and ring lighting, provides clear edge definition and surface detail for a wide range of parts.

SmartScope E7 features a rigid cast base and a precision motorized stage for smooth, accurate motion across all axes. It supports fully automated measurement routines and can be expanded with optional touch probe sensors for true multisensor 2D and 3D measurement capability.

| Standard | Optional | |

| XYZ Travel | 250 x 150 x 200 mm | Extended X-axis, 300 mm |

| XYZ Scale Resolution | 0.1 μm | |

| XY Area Accuracy | E2 = (2.2 + 5L/1000) µm | |

| Z Linear Accuracy | E1 = (3.8 + 5L/1000) μm | E1 = (2.8 + 5L/1000) μm (requires optional E 4.5 lens) |

SmartScope E45 is a floor model 3-axis video measurement system featuring a large travel fixed bridge

design. The fixed lens IntelliCentric™ E optical system and digital zoom provide a high-resolution image engineered for video edge detection metrology. SmartScope E45 also offers:

• Advanced Lighting – All LED coaxial, substage profile, and SmartRing™ light illumination comes standard

• Sturdy, Stable Construction – Parts move on a precision DC motor-driven Y-axis stage while the optics travel in the X-axis mounted on a rigid bridge support structure for metrological integrity.

• Multisensor Versatility – Optional touch probe.

| Standard | Optional | |

| XYZ Travel | 500 x 450 x 200 mm | Extended Y axis, 610 mm; extended Z axis, 300 mm |

| XYZ Scale Resolution | 0.1 μm | |

| XY Area Accuracy | E2 = (2.8 + 5L/1000) | |

| Z Linear Accuracy | E1 = (3.8 + 5L/1000) μm | E1 = (2.8 + 5L/1000) μm (requires optional E 4.5 lens) |

SmartScope® M7 is the next evolution of the worldwide standard in 3D multisensor metrology.

The patented IntelliCentric™-M Optical System features fully telecentric fixed lens optics and VIRTUAL ZOOM™ technology, paired with a high-density 20 MP digital metrology camera and a built-in electronic aperture, delivering an ultra-high-resolution image with low distortion – perfect for high-speed edge detection metrology.

Ultra-High-Resolution Images – All LED coaxial, substage profile, and SmartRing™ light illumination comes standard

Sturdy, Stable Construction – Heavy-duty cast base and integral compound stage with Y-axis center drive for stability. DC Servo motors offer fast, accurate positioning

Multisensor Versatility – Optional TP-20 and TP-200 touch probes, SP-25 Scanning Probe, Feather Probe™, Through-the-Lens (TTL) Laser, Rainbow Probe™, TeleStar® Probe

| Standard | Optional | |

| XYZ Travel | 250 x 150 x 200 mm | Extended X-axis: 300 mm |

| XYZ Scale Resolution | 0.1 μm | 0.05 µm (includes dual X scales) |

| XY Area Accuracy | E2 = (1.8 + 5L/1000) μm | |

| Z Linear Accuracy | E1 = (2.5 + 5L/1000) μm | E1 = (2.0 + 5L/1000) µm (requires touch probe or TTL laser) E1 = (1.5 + 5L/1000) µm (requires TeleStar Probe) |

SmartScope® M20 is the next evolution of the worldwide standard in 3D multisensor metrology.

The patented IntelliCentric™-M Optical System features fully telecentric fixed lens optics and VIRTUAL ZOOM™ technology, paired with a high-density 20 MP digital metrology camera and a built-in electronic aperture, delivering an ultra-high-resolution image with low distortion – perfect for high-speed edge detection metrology.

Ultra-High-Resolution Images – All LED coaxial, substage profile, and SmartRing™ light illumination comes standard

Sturdy, Stable Construction – Compact elevating bridge design with machined in squareness for built-in accuracy

Multisensor Versatility – Optional TP-20 and TP-200 touch probes, SP-25 Scanning Probe, Feather Probe™, Through-the-Lens (TTL) Laser, Rainbow Probe™, TeleStar® Probe

| Standard | Optional | |

| XYZ Travel | 300 x 300 x 250 mm | |

| XYZ Scale Resolution | 0.1 μm including dual Z-axis scales | 0.05 µm |

| XYZ Volumetric Accuracy | E3 = (3.8 + 5L/1000) μm | |

| XY Area Accuracy | E2 = (1.8 + 5L/1000) μm | |

| Z Linear Accuracy | E1 = (3.0 + 5L/1000) μm | E1 = (2.5 + 5L/1000) µm (requires touch probe or TTL laser) E1 = (2.0 + 5L/1000) µm (requires TeleStar probe) |

SmartScope® M45 is the next evolution of the worldwide standard in 3D multisensor metrology.

The patented IntelliCentric™-M Optical System features fully telecentric fixed lens optics and VIRTUAL ZOOM™ technology, paired with a high-density 20 MP digital metrology camera and a built-in electronic aperture, delivering an ultra-high-resolution image with low distortion – perfect for high-speed edge detection metrology.

Ultra-High-Resolution Images – All LED coaxial, substage profile, and SmartRing™ light illumination comes standard

Sturdy, Stable Construction – Parts move on a precision DC motor-driven Y-axis stage while the optics travel in the X-axis mounted on a rigid bridge support structure for metrological integrity

Multisensor Versatility – Optional TP-20 and TP-200 touch probes, SP-25 Scanning Probe, Feather Probe™, Through-the-Lens (TTL) Laser, Rainbow Probe™, TeleStar® Probe

| Standard | Optional | |

| XYZ Travel | 500 x 450 x 200 mm | Extended Y-axis: 610 mm Extended Z-axis: 300 mm |

| XYZ Scale Resolution | 0.1 μm | 0.05 µm |

| XY Area Accuracy | E2 = (2.5 + 5L/1000) μm | |

| Z Linear Accuracy | E1 = (3.0 + 8L/1000) μm | E1 = (2.5 + 8L/1000) µm (requires touch probe or TTL laser) E1 = (2.0 + 8L/1000) µm (requires TeleStar Probe) |

SmartScope® M50 is the next evolution of the worldwide standard in 3D multisensor metrology.

The patented IntelliCentric™-M Optical System features fully telecentric fixed lens optics and VIRTUAL ZOOM™ technology, paired with a high-density 20 MP digital metrology camera and a built-in electronic aperture, delivering an ultra-high-resolution image with low distortion – perfect for high-speed edge detection metrology.

Ultra-High-Resolution Images – All LED coaxial, substage profile, and SmartRing™ light illumination comes standard

Sturdy, Stable Construction – Fixed granite bridge and base rest on a sturdy steel support structure to provide a rigid, orthogonal structure for measurement stability

Multisensor Versatility – Optional TP-20 and TP-200 touch probes, SP-25 Scanning Probe, Feather Probe™, Through-the-Lens (TTL) Laser, Rainbow Probe™, TeleStar® Probe

| Standard | Optional | |

| XYZ Travel | 450 x 600 x 200 mm | Extended Z-axis: 300 or 400 mm |

| XYZ Scale Resolution | 0.1 μm | 0.05 µm |

| XYZ Volumetric Accuracy | E3 = (3.0 + 5L/1000) μm | |

| XY Area Accuracy | E2 = (1.8 + 5L/1000) μm | |

| Z Linear Accuracy | E1 = (2.5 + 5L/1000) μm | E1 = (2.0 + 5L/1000) µm (requires touch probe or TTL laser) E1 = (1.5 + 5L/1000) µm (requires TeleStar Probe) |

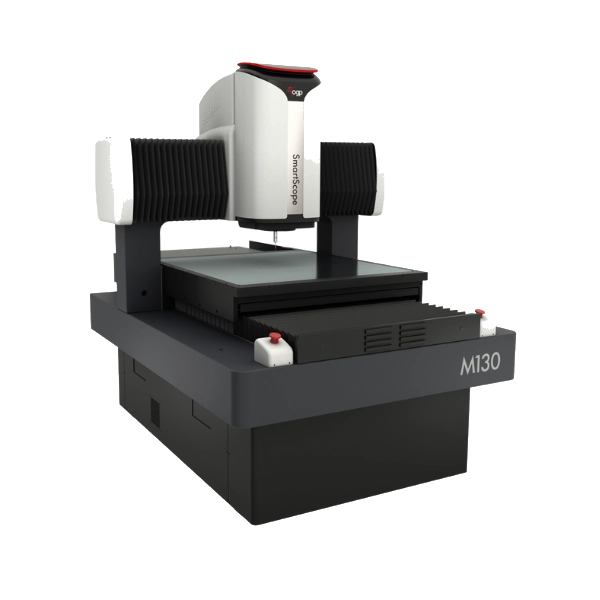

SmartScope® M130 is the next evolution of the worldwide standard in 3D multisensor metrology, ideal for manufacturers inspecting large or heavy parts.

The patented IntelliCentric-M Optical System features fully telecentric fixed lens optics and VIRTUAL ZOOM™ technology, paired with a high-density 20 MP digital metrology camera and a built-in electronic aperture, delivering an ultra-high-resolution image with low distortion – perfect for high-speed edge detection metrology.

Ultra-High-Resolution Images – All LED coaxial, substage profile, and SmartRing™ light illumination comes standard

Sturdy, Stable Construction – Fixed granite bridge and base rest on a sturdy steel support structure to provide a rigid, orthogonal structure for measurement stability

Multisensor Versatility – Optional TP-20 and TP-200 touch probes, SP-25 Scanning Probe, Feather Probe™, Through-the-Lens (TTL) Laser, Rainbow Probe™, TeleStar® Probe

| Standard | Optional | |

| XYZ Travel | 790 x 815 x 200 mm | Extended Z-axis: 300 or 400 mm |

| XYZ Scale Resolution | 0.1 μm | 0.05 µm |

| XYZ Volumetric Accuracy | E3 = (3.2 + 5L/1000) µm | |

| XY Area Accuracy | E2 = (2.0 + 5L/1000) µm | |

| Z Linear Accuracy | E1 = (2.5 + 5L/1000) µm | E1 = (2.0 + 5L/1000) µm (requires Touch Probe or TTL Laser) E1 = (1.5 + 5L/1000) µm (requires TeleStar Probe) |

The SNAP™ 200 is a compact unit equipped with a Large FOV Telecentric lens and a motorized stage with a 250 x 100 mm measuring area. Dual-Mag optics increase capability by providing a much larger magnification range, even within a program. SNAP-X metrology software supports simple “walk up and measure” use, comparison to an electronic overlay, creation and running of automatic programs, including complex measurements and GD&T. AutoID limits operator requirements.

- Large FOV, telecentric dual magnification optics

- Collimated back-light, programmable ring light, and coaxial surface light

- Motorized axes with up to 250 x 100 mm measuring range

- SNAP-X Metrology Software

- Optional ZONE3 Metrology Software

| Standard | Optional | |

| Measuring Unit | Rigid, cast aluminum base and nickel plated worktable; 4 kg load capacity, evenly distributed | |

| Stage | Motorized, programmable 150 mm X and 75 mm Z axis (focus) adjustment with push-button controls | |

| Maximum Measuring Range (X,Y) | 250 mm x 100 mm | |

| Optics | Telecentric, dual optical magnification with 4x high magnification lens | |

| XY FOV Accuracy (E2) | Low Magnification Lens: (4.0 + L/50) µm

4x High Magnification Lens: (2.0 + L/50) µm |

| XY Area Accuracy (E2) | (7.0 + L/50) µm |

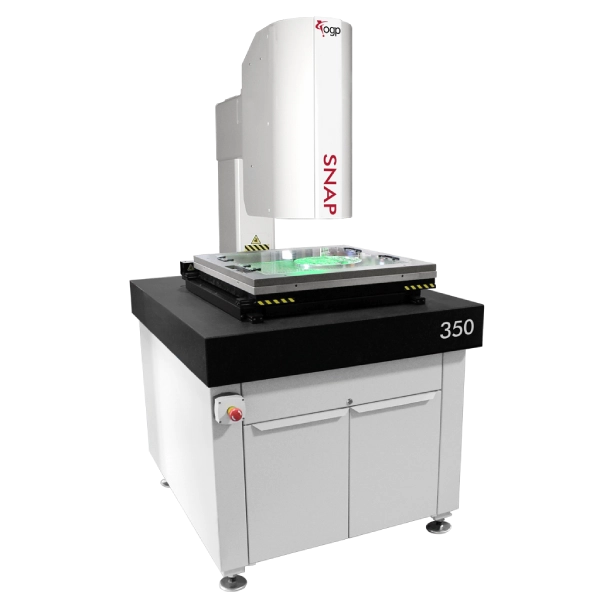

The SNAP™ 350 is a floor-based unit equipped with a Large FOV Telecentric lens and a motorized stage with a large 450 x 450 mm measuring area. Dual-Mag optics increase capability by providing a much larger magnification range, even within a program. SNAP-X metrology software supports simple “walk up and measure” use, comparison to an electronic overlay, creation and running of automatic programs, including complex measurements and GD&T. AutoID limits operator requirements.

- Large FOV, telecentric dual magnification optics

- Collimated back-light, programmable ring light, and coaxial surface light

- Motorized axes with up to 610 x 450 mm measuring range

- SNAP-X Metrology Software

- Optional ZONE3 Metrology Software

MAX MEASURING RANGE (MM)

Standard

450 x 450 mm

Optional

Extended X-axis, 610

OPTICS

Standard

Telecentric, dual optical magnification with 100 mm low mag field of view and 4X high magnification lens

Optional

10X high mag lens in lieu of 4X lens

Fusion® 400 systems from OGP are 3D capable, high accuracy large field-of-view (LFOV) multisensor floor model systems with a measuring range of 400 x 300 x 250 mm.

Optics – Dual optical paths with an instantaneous magnification change between a low mag with 100 mm viewing area and high mag for small feature measurement and autofocus, fully telecentric for image accuracy.

Stable Platform – Solid cast base with a granite surface plate and compound stage allow for extremely accurate measurements.

Multisensor Versatility – Optional touch probe, Scanning Probe, TeleStar TTL laser, Rainbow Probe, and 4th and 5th axis rotary indexers. All sensors share are placed precisely on the optical centerline by the patented rotational deployment mechanism

Productivity – 3D CAD-based ZONE3 metrology software, with integral AutoID and FeatureExtractor functions for one touch measurement. Full field image processing and high-speed cameras allow entire scenes to be measured instantly

| System | Standard | Optional |

| XYZ Travel | 350 x 250 x 250 mm | |

| XYZ Measuring Range (max) | 420 x 320 x 250 mm | |

| XYZ Scale Resolution | 0.1 μm | 0.05 µm |

| XY Area Accuracy | E2 = (1.8 + 4L/1000) µm | |

| Z Linear Accuracy | E1 = (2.0 + 5L/1000) µm (requires optional scanning probe or TeleStar Plus TTL Laser) | |

Metrology Grade 3D Scanning – Ideal for measuring complex shapes in a variety of colors and finishes due to a 360° rotary table and vertical motion. Excels in rapid prototyping, manufacturing, quality control, and reverse engineering applications.

Ease of Use – Scans can be initiated with one click, delivering consistent measurement results by any operator. Scanning parameters are easily selected and saved – there is no need to write special code.

Accurate, High Density Point Data– The SG108 scanhead moves vertically on a high precision motion assembly and can obtain more than 1,500,000 points per second.

BENCHTOP SYSTEM FOR FULLY AUTOMATED 3D LASER SCANNING

Max Scan Volume (mm)

Standard

300 L x 100 Ø

ShapeGrabber Ai620 3D scanner is a precision, metrology-class 3D scanner. Ai620 measures the complete surface of complex shaped plastic, metal, and 3D printed parts in minutes with a high density of data points.

Ai620 is easy to use and highly automated. After an initial scan, the same scanning parameters may be used for subsequent parts, delivering consistent results irrespective of operator skill or experience. There is no need to write special code. ShapeGrabber Ai620 offers:

Faster Speed – When used at its maximum scan volume, the SG198 scanhead measures data at 155,000 points per second. For parts that do not require the full scan volume, the data rate increases to more than 1.5 million pts/s. Optional 25° tilt mechanism for faster, more complete part coverage without part reorientation.

Better Data Quality – The SG198 scanhead features an optical arrangement that draws on OGP’s 75+ years of experience designing optical systems for precision measurement. The sensor optics provide extremely low noise data that far outperforms other 3D scanning technologies.

Higher Resolution – The built-in 5MP imager delivers depth resolution and data densities for the most challenging applications. The combination of such high resolution in a relatively large volume makes the entire process of measuring complex shaped parts faster and easier

Wider Dynamic Range – ShapeGrabber scanheads offer high dynamic range, accurately measuring a wide variety of materials, colors, textures, and finishes without the need for surface treatments. The SG198 scanhead handles the full range – from matte black plastic, to bare metal, to grainy castings and 3D printed parts.

PRECISION AUTOMATED 3D LASER SCANNER

Max Scan Volume (mm)

Standard

600 L x 185 Ø with SG198 Scanhead

TurnCheck™ Series-10 systems offer a fast, easy way to measure shafts, cylinders and other turned, ground or extruded parts. Just place the part and press GO.

TurnCheck Series-10 systems are precision optical measuring instruments designed for shop floor environments. TurnCheck systems are rugged and reliable, accommodating parts up to 175 mm diameter by 800 mm in length. TurnCheck will scan and measure a part in seconds using its telecentric, large field of view optical system. With 100 mm wide field of view and vertical range of 400, 600 or 800 mm, TurnCheck Series-10 systems can handle just about any turned or ground part. TurnCheck software allows easy measurement of diameters, lengths, distances, angles, radii, form, position, cylindricity, and runout – and can output point data for external analysis.

The movable tailstock assembly is designed to be easily operated with one hand for precision mechanical alignment of the workpiece. Additional optional workholding kits that fit into the spindle accommodate workpieces that do not have centers. Granite base support for rotary provides a rigid base and isolates vibration.

MEASUREMENT CAPACITY

Measuring Range (mm)

10|40 – 400 L x 100 Ø

10|60 – 600 L x 100 Ø

10|80 – 800 L x 100 Ø

MAXIMUM PART SIZE (MM)

Standard

10|40 – 400 L x 175 ∅

10|60 – 600 L x 175 ∅

10|80 – 800 L x 175 ∅

Focus™ Contour Projector® systems are high quality, full-function 14” optical comparators with the most advanced technology available and offer:

Vectored light control – Versatile TruLight® LED lighting illumination

Keep lenses safe and ready for use – 3 position internal lens turret

Ideal for real world, shop floor environments in a benchtop configuration – Rigid, all steel construction and solid metal castings

Optional VidiProbe video measurement, optional motorized servo drives, and optional Projectron automatic internal edge detection

HIGH QUALITY, FULL-FUNCTION 14” OPTICAL COMPARATORS WITH THE MOST ADVANCED TECHNOLOGY AVAILABLE

XY Travel

Standard

12” x 5”

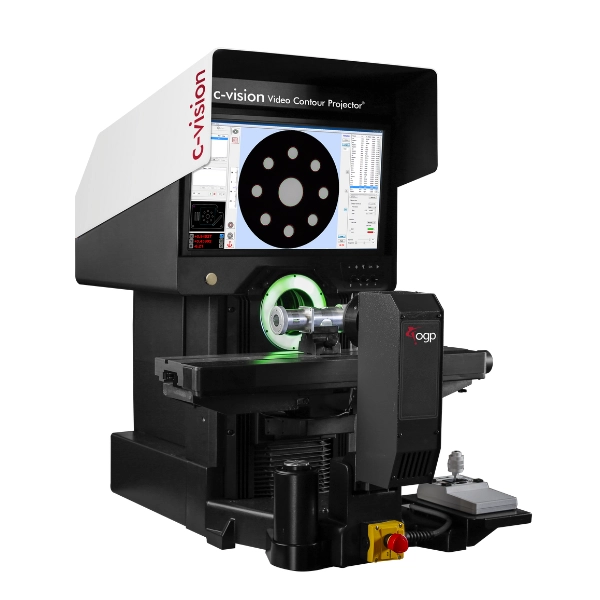

c-vision™ Benchtop Video Contour Projector® is an easy to use, dual-magnification benchtop video contour projector. This rugged horizontal optical comparator features a compact footprint that uses very little floor space. Its rugged design and 60 lb load capacity put advanced automatic video measurement capability to work right where it is needed. Precision optics and SNAP-X Compare electronic overlay charts make comparative inspections easy. c-vision Benchtop provides:

Accurate Image with exceptionally low distortion over entire 3-inch viewing area – Telecentric dual magnification optical system with advanced digital imaging technology

Shop hardened and convenient benchtop – High payload capacity, easy to use interface. Motorized XY table motion with precision linear scales and manual fine adjusters

Display both standard and custom overlay charts – SNAP-X Compare software

AN EASY TO USE, DUAL-MAGNIFICATION BENCHTOP VIDEO CONTOUR PROJECTOR

XYZ Travel

Standard

15” x 6” x 2”

Lazer 200 is an innovative non-contact measuring system that uses laser scanning and video support for surface topography measurements.

The Digital Range Sensor (DRS™) laser delivers high quality non-contact laser scans of critical part surfaces.

Lazer 200 features a mechanically innovative “elevated bridge” design that creates the most compact system of any machine with comparable travel

Chassis axial straightness and perpendicularity are machined in Z-axis travel keeps the DRS laser within its capture range throughout the scan

Integral on-axis video imaging is used to locate the part, set datums, and choose laser scan start and stop point

XYZ Travel (mm)

Standard

200 x 200 x 100

Illumination

Linear white LED surface, LED substage

Laser Scanning Resulution

0.125 µm