Minor Products

Essential supporting equipment such as Smart UPS units, power management devices, test tools, and protective accessories. These products enhance system stability, ensure uninterrupted operation, and provide reliable backup for critical equipment.

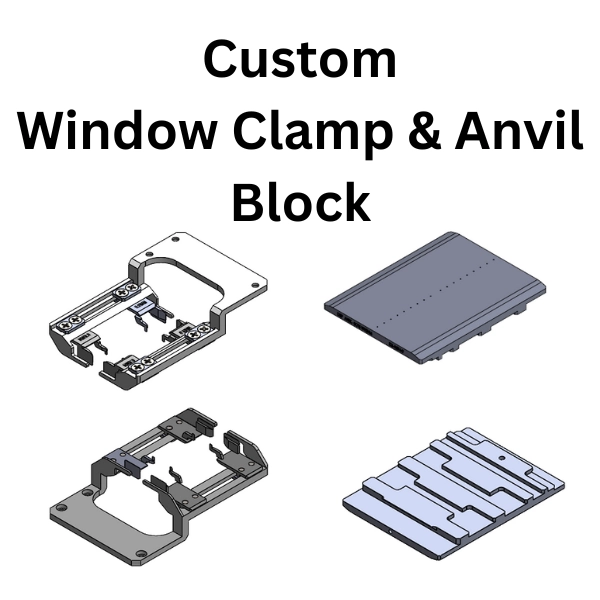

EQUIPPED WITH SMART ZERO FUNCTION

Displacement of zero point detection will be easier and smooth by smart zero function

BUILT–IN USB MEMORY UNIT

Enable the tester to perform more efficient load testing. When use in production line, it is not necessary to bring a personal computer into the line. A USB Thumb Drive with stored test result can be taken out from the tester to examine in other place. Measurement conditions can also be store in the USB Memory.

TESTER DATA STORING

With Built in 16GB memory able to store about 10,000 testing result

DISPLAY AND PRINTING

You can see test results and curve of load displacement with high density LCD on the MAX tester and print out through the built-in printer. The CENTRONICS INTERFACE enables the external printer to print test results out in form of test report. (ESCIP based)

DATA PICK UP FUNCTION

The standard test program on the MAX can perform most of general compression/tension load test. Its data pick-up function can pick specific data from test results.

PROGRAM CHANGE THOUGH USB PORT

Since the MAX series is operated with a Test Program that has been installed. It is easy to change the Test Program. In other words, one MAX tester can be use for multiple purposes.

MULTIPLE LANGUAGE TESTER

Tester consists of English, Japanese, Korean & Chinese (Simplified & Traditional) Language. Globalization of manufacturing support and can be used in most part of the world.

The whole series meets 05 grade (Highest Grade) of JIS B 7738 Coil Spring Compression / Tension Tester.

• In addition to 1 Step , 2 -Step, 3 -Step Automatic Tests, Free Length, Initial Tension, Solid Length, Peak Load can be measure.

• Unit select able among N, gf, kgf, lbf and inch covered by English version.

• Measurement range can be changed through 2- step high-low range automatic switch over function, there by eliminating unnecessary steps.

• Dual unit (gf, kgf and N) printing is possible through printer setting. 50 Tests conditon can be store by registering model number.

• Test can start immediately once test condition are recall.

• Passing range or Good / Bad assessment is done visually by using screen display and alarm.

• Can connect to Mitutoyo Digimatic Caliper, Micrometer etc.. And data can be printed out.

• Ascend and descend buttons are equipped with inching function.

• Simple movements of 1mm, 0.1mm, (0.001mm) are possible.

“Load test with length input”, load is measured automatically once length is input. (All-Type)

”Length test with Load input”, spring length is measured automatically once load is input. (S-Type, H-Type)

”Deflection load test”, load is measured automatically based on deflection amount resulted from free length. (S-Type, H-Type)

”Load deflection test”, deflection amount corresponding to applied load resulted from free length is measured automatically.

”Step load test”, load is measured as length is step automatically fixed intervals. (H-Type)

”Step length test”, length is measured as load is step automatically fixed intervals. (H-Type)

Model IT-5 IT-20

Units N.m, kgf.cm, ibf.in

Effective Range +/- 0.02 ~+/- 5.N.m +/- 2 ~ +/- 20N.m

Resolution 0.001N.m 0.01N.m

Accuracy +/- 0.5% of F.S

Maximum Allowable Torque 150%

Maximum Memory Data 511

Comparator Upper & Lower Limit Setting of Specification

A/D Convertor 16 Bit

Response 640Hz/sec

Battery Operated Ni.MH Battery with Power Adaptor

Operating Temperature 10~40 Deg C & Humidity of 85% & Below

Data Output RS232C Interface

Dimension W230 x H60 X D149mm

Mass Approximately 3.3kg

- Easy operation

- Peak hold function

- Comparator function

- Memory function

- Automatic power off

- Local Newton value input

• Deliver High Precision Measurement via 3 load cells even if there is unbalance load. The tester alone can meet a variety of specifications

such as JIS K6400-2, JASO B408 & etc.

• This UFT series can satisfy a variety of urethane foam test. The 3 load cells enable this tester to deliver high precision load detection even in the presence of unbalance load. Test sample placed on the wide test table (1000 x 700mm) can be measured just as it is. For instance a car seat can also be place on the test table and measurement can take place as it is. The installed urethane foam testing program can change “%”, “Cycle” and “Time”.

• The tester also meets the Hardness Test and Deflection Test Specifications of Automotive Manufacturer under fixed load.

• Test Conditions and Results can be stored in USB Memory and export to Microsoft Excel for Test Inspections. The tester also adopts “Program Load” via USB Memory and it can also meet requirements of any custom made test.

• External control test using PC Software is also possible.

- Hardness Test JIS K6400-2 Method A, B, C & D

- Compression Deflection Test JIS K6400-2 Method A-1 & A-2

- Compression Deflection Test JIS K6400-2 Method B

- Micro Displacement Spring Rate Test

- Stress Relaxation Test

- Compression Load Test

- External Control Test via PC

- LEAF-5000 is a high capacity leaf spring tester, mainly use in the automotive industries for trucks and lorry.

- Tester able to preset distance to find the load and also preset the deflection of leaf spring to find load.

- Software program is available to enhance the testing with data and testing condition storage.

–>LIQUID CRYSTAL DISPLAY TOUCH-PANEL

Loaded with a LCD display with backlight. The hardness tester secures very clear and high visibility

–>AUTO START

After setting the reference load, the test load is applied automatically . (Manual start is also possible)

–>EASY SETTING

Reference load can be easily set with a bar graph display on the bright screen and electronic sound. More over, an error-preventing device is also mounted.

–>PLASTIC MEASURING SYSTEM

Specific measuring method for plastic in compliance with ASTM and JIS is activated by one-touch easy operation. Time for reading the value after unloading the test load can be set freely

–>VARIOUS DATA PROCESSING FUNCTIONS

It makes acceptance and rejection judgement, conversion to other scales, and tabulation and computing for data memory (256 data), maximum value, minimum value, variation, average, standard deviation etc.

–>TRADITIONAL DIAL CHANGE-OVER SYSTEM

Dial changeover systems make change the test load easily by turning the dial.

Accordingly the design is dust-proof including the weights for test load.

–>APPLICABLE TO CE AND SAFETY

Safety design applicable to EU low voltage command, EMC command and machine command. In addition to high-rigidity body , overturn-preventive metal fittings are attached as standard to prevent overturning by earthquakes etc.

- ASKER Model F – ASKER Model FP

Exclusive type for foam materials, allowing measurement by placing the tester on the object o measurement.

In addition to Model F, Model FP is available for powder puff. - ASKER Model CS

This features larger indentor and a more strong spring compared to ASKER C, thereby making it more suitable for polystyrene foam. - ASKER Model JA

A hardness tester which conforms with the Japanese Industrial Standards JIS K 6301. One of the most popular types in Japan, but has recently been gradually replaced with the ISO-specified Type A - ASKER Model B

It uses the same spring load used in ASKER Model A. It adopts a conical indentor similar to that of Model D, so as to be applicable to harder measuring objects than can be measured by Model A.

It is useful for hardness measurement of unglazed pottery clay and ceramics

in green condition. - ASKER Model D

Similar to ASKER Model A, this model is defined as ‘Durometer Type D’ as described in various domestic and international standards. It is in widespread

use for hardness measurement of plastics and hard rubber. - ASKER Model C – ASKER Model C2

ASKER Model C is intended for hardness measurement of soft rubber, sponge, foamed elastomers, wound threads(yarn package), rolled films, potter’s clay(kaolin), and other such soft materials.

For even softer materials, Model C2 is available - ASKER Model A

Has been used for wide applications since being standardized in the ISO. - ASKER Model JAL

Especially useful for recessed and/or smaller measuring areas.

In addition to the standard Mode JAL, long presser foot types are available for another Model applications. - ASKER Model JC

ASKER JC have those hardness testers described in JIS K 6301 as ‘suitable for samples found to have a hardness value above 70 according to Model A’. It features higher resolution for hardness measurement of hard rubber.

Precision styli for metrology

Renishaw offers a comprehensive range of precision styli for touch probes. Learn how the quality of styli and accessories play a vital role in industry measurement technology and how Renishaw can support you.

For IT professionals in small to medium businesses, EasyUPS Online provides basic power protection for unstable power conditions, ensuring consistent and

reliable connectivity at the most critical moments. APC Easy UPS Online is a versatile, high quality, cost competitive UPS developed to handle a wide voltage

range, and inconsistent power conditions; delivering the quality millions of IT professionals trust around the world.

VOYAGER EXTREME PERFORMANCE (XP) 1470g

Durable, Highly Accurate 2D Scanner Designed for in-store retail environments requiring a highly accurate 2D scanning

solution in a durable form factor, the Voyager™ Extreme Performance (XP) 1470g scanner delivers industry-leading scanning capability on traditional barcodes and digital screens –even on damaged and difficult-to-read codes.

The Honeywell PC42E-T is a compact, high-speed, and high-resolution desktop printing solution designed for mid-volume printing businesses that require reliable and continuous operation. With its array of intelligent features and user-friendly

design, the PC42E-T is well-suited for various industries such as retail, transportation and logistics, light manufacturing, and warehousing.

Machine Vision and Industrial Fixed Scanners

Fixed Industrial Scanners

Automate Track and Trace Throughout the Supply Chain

Zebra’s fixed industrial scanners automatically track and trace items from production to distribution. Easily keep track of every part and package with a model for every application. Upgradeable features grow as you do to meet the evolving needs of your business. From advanced scanning to machine vision, Zebra provides it all. And with Zebra Aurora™, set up, deploy and run scanners from a single unified software platform.

Enhance Performance with Enterprise Mobile Computers, Printers, Scanners, Tablets, Kiosks and More

More is expected of you every day, and as a result, you expect more from your technology — more efficiency, more accuracy, more durability. That’s why Zebra engineers scanners, mobile computers, tablets and printers with one purpose — to help you perform even better. Using decades of innovation, we design every product with you in mind. Your day-to-day tasks. Your work conditions. Your pressures. Discover how with scanners, mobile computers, tablets and printers with features and form factors made for you.

Basic Model with Improved Convenience

- Freely set responsiveness or stability

- Connect with a computer via USB or RS232C

- Perform stable measurements in combination with an ionizer

Features

-

1. Easy Settings Enable Responsiveness and Stability to be Freely ChangedResponsiveness becomes very important when weighing fixed amounts of powders and liquids. On the other hand, stability is required when weighing substances in environments subject to drafts or vibrations. The AT-R balances are equipped with a 5-stage indicator. It is easy to switch between a response focus (R) and a stability focus (S) during measurements.

-

-

3. Addition of an Ionizer Increases Measurement ReliabilityThe optional STABLO™-AP ionizer (static remover) quickly removes static from samples and containers, without creating a draft. This prevents reproducibility errors and fluctuations in measurement values due to static electricity. The static elimination can be enhanced by placing flasks in the AP Holder (sold separately).

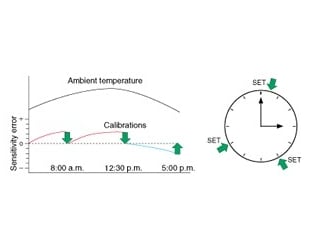

The line of Shimadzu top-loading balances is engineered with the UniBloc mechanism, resulting in unrivaled response, stability and durability. Powerful features support any imaginable weighing application. The UW Series includes internal calibration and fully-automatic calibration functions.

Features

The Energy Dispersive X-ray Fluorescence spectroscopy (ED-XRF) is a non-destructive analytical technique for identifying and quantifying elemental compositions in solid, powder, and liquid samples. It is widely used for non-destructive elemental analysis for quality and process control in applications including metals, chemicals, polymers, environmental testing, food safety, and pharmaceuticals, etc.

Shimadzu has been a world leading manufacturer of high-quality ED-XRF spectrometers and provides a comprehensive product lineup including the EDX-7200 flagship model, which supports compliance of the newest consumer and environmental regulations; the EDX-8100, which offers a high level of accuracy and speed when analyzing elements and can also detect ultra-light elements; and the EDX-LE/EDX-LE Plus, which are designed specifically for screening elements regulated by RoHS/ELV directives. Learn more about our full lineup and how you can enhance your laboratory performance below.

Fourier transform infrared spectroscopy (FTIR) is an analysis technique used mainly for structural estimation (qualification) of organic compounds of solid, gas and liquid samples. When molecules are irradiated with infrared rays, they absorb infrared rays equivalent to the vibrational energy between the atoms that make up the molecules. A Fourier Transform Infrared (FTIR) Spectrophotometer is used to estimate and quantify the structure of compounds by examining the degree of absorption. FTIR is frequently used in a wide range of structural analysis and non-destructive measurement applications.

Due to the simplicity and versatility of the measurement, FTIR is used for structural identification in many industries and applications. FTIR is incredibly useful for the pharmaceutical industry for both research and quality control of existing products.

Shimadzu offers a complete FTIR product lineup, from the compact FTIR, IRSpirit-X, which provides reliable, versatile and high-performance, and IRXross which provides stable FTIR analysis, to the high-end IRTracer-100 for sophisticated research. Shimadzu FTIR systems, offering high resolution, high sensitivity and simplicity, offer a wide range of solutions.

Radiographic Testing (RT) is a non-destructive testing (NDT) method which uses X-rays to examine the internal structure of manufactured components to identify any flaws or defects. Microfocus X-ray CT scanning is a 3D non-destructive testing (NDT) technique that allows the testing and 3D analysis of various materials in a non-destructive manner. It is widely used in the measurement of automotive parts, resin molded parts, bones, printed circuit boards (PCB), batteries, polymers, etc.

Shimadzu provides a comprehensive lineup of microfocus X-ray CT systems and solutions for high resolution 3D imaging of a wide variety of samples. Our product lineup includes the XSeeker 8000 bench-top X-ray computed tomography (CT) system, which enables clear observation of metal parts included in compact designs; and the inspeXio 7000 high-performance microfocus X-ray CT system, boasting higher resolution and higher contrast CT images with an intuitive user interface. Learn more about our full lineup below.

Radiographic Testing (RT) is a non-destructive testing (NDT) method which uses X-rays to examine the internal structure of manufactured components to identify any flaws or defects. Microfocus X-ray inspection is a 3D non-destructive inspection (NDI) technique that allows the testing and 3D analysis of various materials in a non-destructive manner. It is used in a wide range of industries, including the electronics, automotive, semiconductors, and aerospace industries.

Shimadzu provides a comprehensive lineup of microfocus X-ray inspection systems and solutions for high resolution inspection of electronic assemblies, components, and printed circuit boards (PCB). Our product lineup includes the Xslicer SMX-1010/1020, boasting significantly improved image quality and a simplified workflow; and the Xslicer SMX-6010, featuring high-accuracy images with a wide dynamic range that enables detailed observation of internal structures and defects. Learn more about our full lineup below.

Single quadrupole mass spectrometry is a mass detection technology that can be adapted to a wide range of applications. Shimadzu’s single quad GC-MS offers ultimate high-speed and high-efficiency analysis with unparalleled performance to meet your analysis needs in fields such as environmental pollution monitoring, forensics, material science, and more.

Shimadzu’s single quadrupole GC-MS systems provide reliable routine analysis and smart solutions for maximizing the potential of laboratories. Our portfolio includes the GCMS-QP2020 NX and the GCMS-QP2010 SE single quad GC-MS. Browse Shimadzu’s entire product range below.

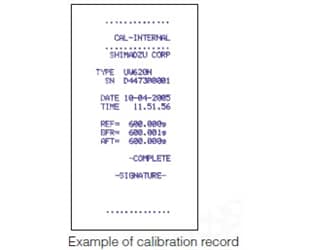

Custom Fabrication of Jigs & Fixtures

We provide custom-designed and precision-fabricated jigs and fixtures tailored for the semiconductor, electronics, and automotive industries, where accuracy, repeatability, and reliability are non-negotiable.

Our jigs and fixtures are engineered to improve production efficiency, ensure dimensional consistency, and reduce operator variability across inspection, assembly, machining, and testing processes. Each solution is built based on your actual application requirements, machine interface, tolerances, and workflow, ensuring seamless integration into your existing production line.

Key Capabilities & Benefits:

-

Precision-built jigs and fixtures for inspection, measurement, alignment, and assembly

-

Designed for CMM, vision systems, laser systems, and automated equipment

-

Supports high-mix, high-precision manufacturing environments

-

Improves repeatability, cycle time, and measurement accuracy

-

Durable materials suitable for cleanroom, ESD-sensitive, and production-floor use

-

Fully customized—from concept, design, fabrication, to on-site fitting and validation

Whether for semiconductor packages, PCB assemblies, automotive components, or precision parts, our solutions are built to hold parts exactly where they should be—every time. Old-school precision, modern execution. Built right the first time. 🔧✨

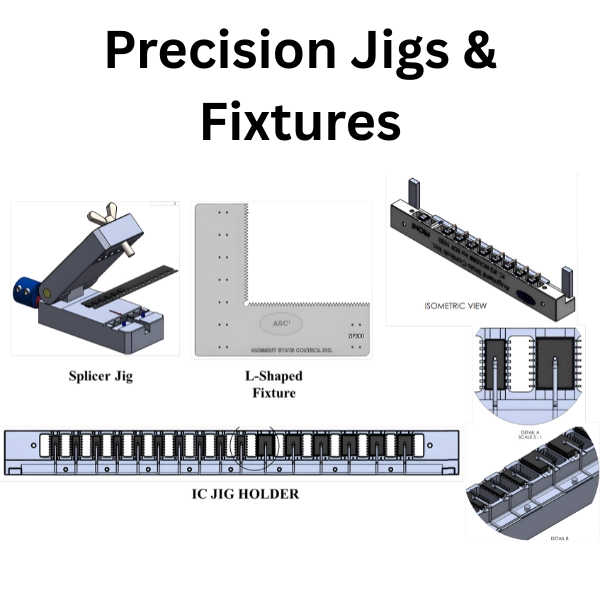

Custom Fabrication of Clamps & Inserts for the Semiconductor Industry

We specialize in the custom design and fabrication of precision clamps and inserts engineered specifically for the stringent requirements of the semiconductor industry, where accuracy, cleanliness, and repeatability are critical.

Our clamps and inserts are designed to secure delicate components without inducing stress, deformation, or contamination, making them ideal for inspection, metrology, assembly, testing, laser processing, and automation applications. Each solution is tailored to the exact geometry, material, tolerance, and process conditions of the customer’s application.

Key Capabilities & Benefits:

-

Custom clamps and inserts for wafers, leadframes, packages, substrates, and precision parts

-

Designed for vision systems, CMMs, laser systems, and automated equipment

-

High-precision machining to support tight tolerances and repeatable positioning

-

Materials compatible with cleanroom, ESD-sensitive, and chemical-resistant environments

-

Minimizes part movement, vibration, and measurement error

-

Reduces setup time and improves process consistency

-

Built for high-volume and high-mix semiconductor manufacturing

From concept and design to fabrication and validation, our clamps and inserts are built to protect critical parts while maximizing process accuracy and throughput. Classic precision, modern execution—because in semicon, microns matter. 🔬✨

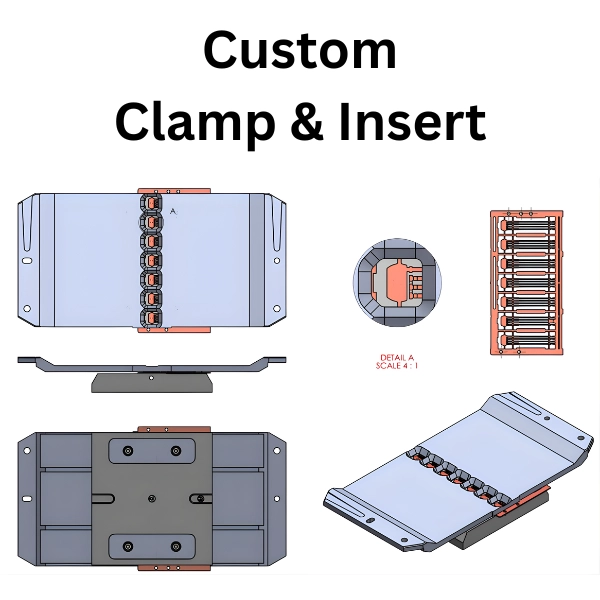

Custom Fabrication of Window Clamps & Anvil Blocks for the Semiconductor Industry

We provide custom fabrication of precision window clamps and anvil blocks designed to meet the high-accuracy, low-stress requirements of semiconductor manufacturing and inspection processes.

Our window clamps are engineered to securely hold delicate semiconductor components while maintaining a clear inspection or processing window, making them ideal for optical measurement, laser applications, metrology, and vision systems. The design ensures maximum stability without obstructing critical areas, enabling accurate, repeatable results.

Our anvil blocks are precision-machined to serve as stable reference and support surfaces for pressing, alignment, bonding, inspection, and measurement operations. Built for flatness, rigidity, and durability, they help maintain consistent part positioning and process reliability, even in high-volume environments.

Key Features & Benefits:

-

Custom-designed window clamps and anvil blocks based on part geometry and process requirements

-

Supports applications such as laser decapping, cross-sectioning, inspection, metrology, and automation

-

High-precision machining for tight tolerances and repeatable positioning

-

Minimizes stress, deformation, and vibration on sensitive semiconductor parts

-

Materials compatible with cleanroom, ESD-safe, and contamination-controlled environments

-

Improves measurement accuracy, process stability, and throughput

-

Suitable for R&D, pilot lines, and full production

From design validation to final fabrication, our window clamps and anvil blocks are built to protect critical components while enabling precise, unobstructed access for inspection and processing—because in semiconductor manufacturing, control, consistency, and microns matter. 🔬⚙️

If you want, I can also:

-

condense this into a one-paragraph website version

-

make a highly technical spec-style description

-

or tailor it for laser, metrology, or FA equipment applications