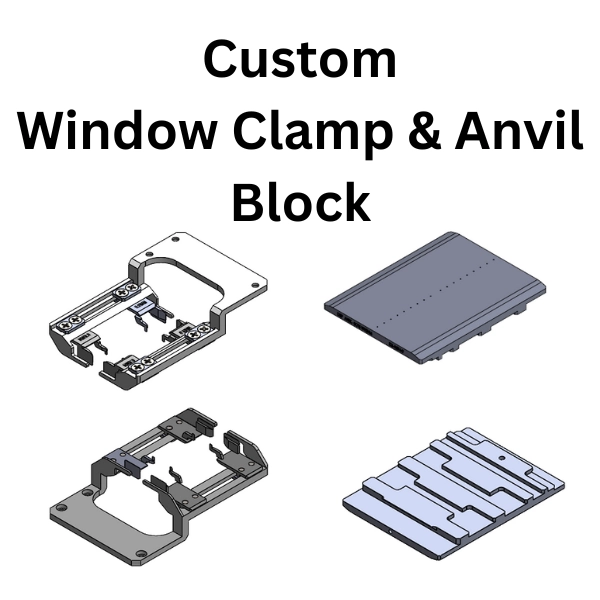

Custom Fabrication of Window Clamps & Anvil Blocks for the Semiconductor Industry

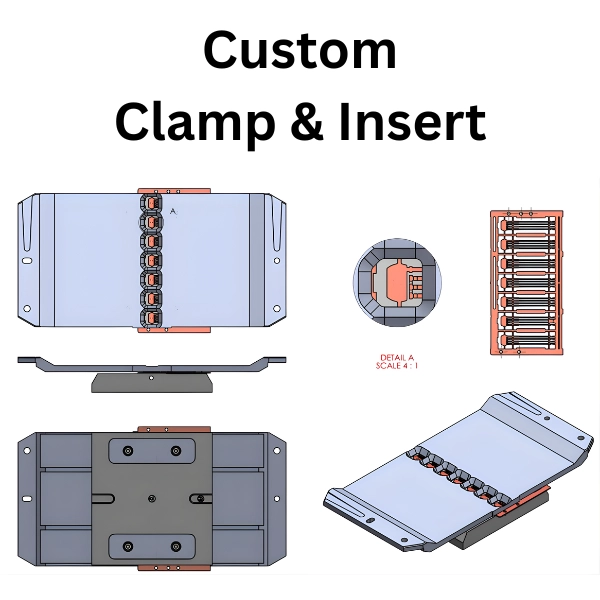

We provide custom fabrication of precision window clamps and anvil blocks designed to meet the high-accuracy, low-stress requirements of semiconductor manufacturing and inspection processes.

Our window clamps are engineered to securely hold delicate semiconductor components while maintaining a clear inspection or processing window, making them ideal for optical measurement, laser applications, metrology, and vision systems. The design ensures maximum stability without obstructing critical areas, enabling accurate, repeatable results.

Our anvil blocks are precision-machined to serve as stable reference and support surfaces for pressing, alignment, bonding, inspection, and measurement operations. Built for flatness, rigidity, and durability, they help maintain consistent part positioning and process reliability, even in high-volume environments.

Key Features & Benefits:

-

Custom-designed window clamps and anvil blocks based on part geometry and process requirements

-

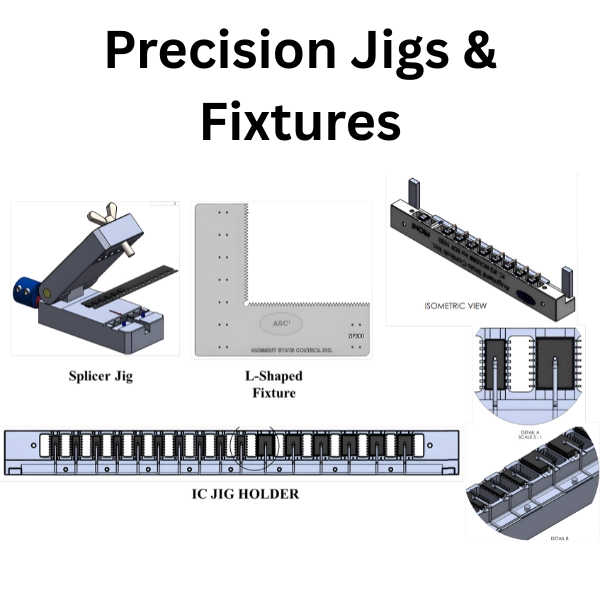

Supports applications such as laser decapping, cross-sectioning, inspection, metrology, and automation

-

High-precision machining for tight tolerances and repeatable positioning

-

Minimizes stress, deformation, and vibration on sensitive semiconductor parts

-

Materials compatible with cleanroom, ESD-safe, and contamination-controlled environments

-

Improves measurement accuracy, process stability, and throughput

-

Suitable for R&D, pilot lines, and full production

From design validation to final fabrication, our window clamps and anvil blocks are built to protect critical components while enabling precise, unobstructed access for inspection and processing—because in semiconductor manufacturing, control, consistency, and microns matter. 🔬⚙️

If you want, I can also:

-

condense this into a one-paragraph website version

-

make a highly technical spec-style description

-

or tailor it for laser, metrology, or FA equipment applications